Just this minute I received an email from the Project Shield subscription, and for anyone who didn’t sign up but is interested to hear what they have to say – here it is.

We’re getting closer to the launch of our NVIDIA® Tegra® 4-powered Project SHIELD portable gaming console, so we thought you’d like to get a sneak peek into the manufacturing process.

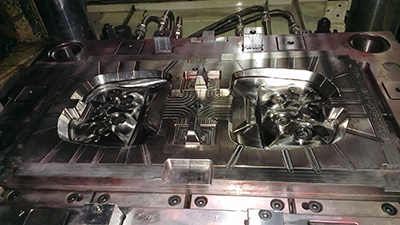

The photo you see below shows the production mold that’s used to craft the ergonomic casing that houses Project SHIELD’s high-powered components: Tegra 4, 5-inch 720p HD retinal touchscreen, Stereo Bass Reflex Speakers, WiFi, accelerometer, gyro, a massive battery, and more.

To create the casing, we inject a polycarbonate material into the RHCM (Rapid Heat Cycle Molding) tool at 10,800 PSI and 300 degrees Celsius. We use a polycarbonate mixture comprised of 90% Sabic 500ECR-739 PC and 10% glass. This material and injection molding process ensures a sturdy yet lightweight casing that will deliver hours of gaming with no fatigue.

For anyone that missed it, Shield is Nvidia’s take on handheld Android gaming. It’s a 5 inch clamshell device and will be one of the first machines to utilise their Tegra SoC. Still no word on pricing or release date, but it looks like things are moving along nicely, which is great.

Pretty cool of Nvidia to give us some insight into their manufacturing process I reckon, I can’t recall any of the Big Three ever doing something like this in the past. If you’d like to subscribe to their mailing list, just head over to the website and stick your email address in the top right corner!

OMG 349$

http://www.theverge.com/2013/5/14/4329008/nvidia-shield-price-specs-release-date-preorders-begin-hands-on-preview

So they are molding plastic. Super! Who isn’t these days?

MAKE WITH!

Its price will be dreadful! I hope they take that in to account. Good post though.